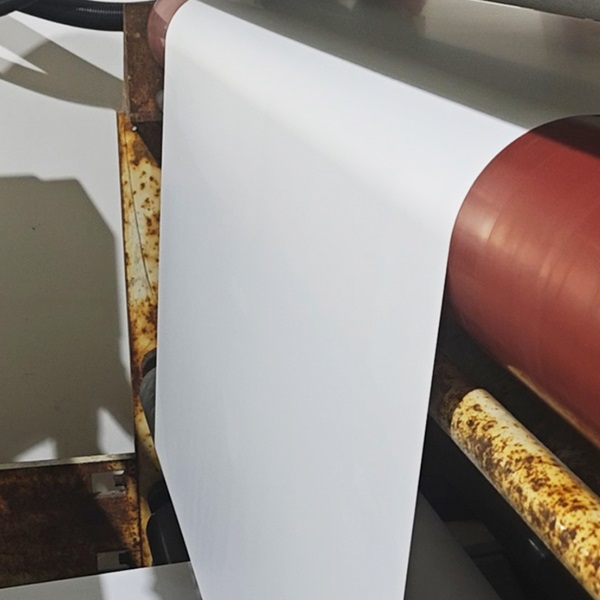

PP synthetic paper is an environmentally friendly material mainly made from polypropylene (PP) resin and processed through special techniques such as coating with EVA. It combines the water-resistant, moisture-proof and durable properties of plastic with the printability of paper.

PP synthetic paper opens up a new future for packaging and printing

I. Performance Characteristics and Advantages

1. Physical Properties

Strong tear resistance, superior to ordinary paper, suitable for more extreme outdoor environments.

Low density, light weight, convenient for transportation and processing.

Does not deform easily under normal conditions, suitable for long-term storage or use in various environments.

2. Chemical Properties

Waterproof and moisture-proof, resistant to chemical corrosion (acid, alkali, and organic solvents), suitable for various chemical fields.

Environmentally friendly, can be used in the food industry.

3. Through special processes such as EVA, the adhesion of ink is enhanced, the printed colors are brighter, and the pattern reproduction is more accurate, suitable for various printing methods such as offset printing, flexographic printing, and digital printing.

II. Diverse Application Scenarios

1. Food and Pharmaceutical Industry: Can be made into various packaging bags for use, with waterproof and moisture-proof properties, which can extend the shelf life of food and medicine, and is scratch-resistant and wear-resistant for easy transportation.

2. Daily Chemical Packaging and Labels, etc.: Suitable for various industry labels, resistant to friction and aging, and can maintain clear information even in low-temperature or humid environments.

3. Advertising Industry: Can be made into outdoor posters, light box advertisements, and exhibition boards, resistant to sun and rain, with a longer service life.